IMPORTANCE OF STANDARD OPERATING PROCEDURES

EXPERT PRE-PAINT STANDARD OPERATING TECHNIQUES FOR INCREASED EFFICIENCY & PRODUCTIVITY

A Standard Operating Procedure (SOP) process creates consistency and efficiency for ensuring optimal results and customer satisfaction!

Learn about the pre-paint body filler repair process to help make your shop locations become more productive, avoid rework, and save you money.

The Do’s and Don’ts of Body Filler

- Shop Safety Procedures

- Read product batch dates

- Surface Preparation to maximize repair longevity

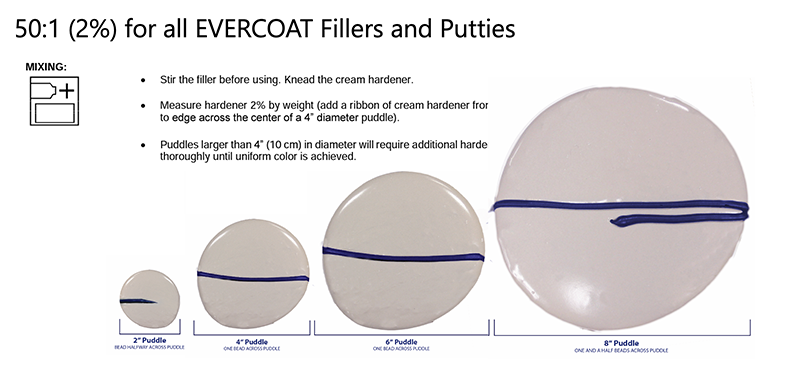

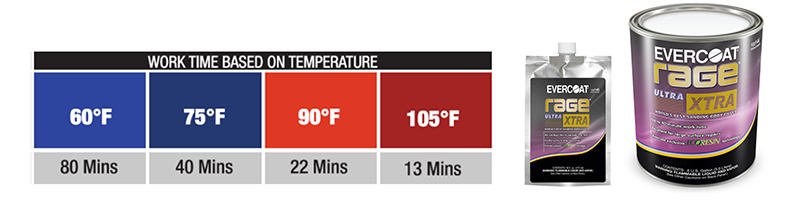

- Body filler catalyzation

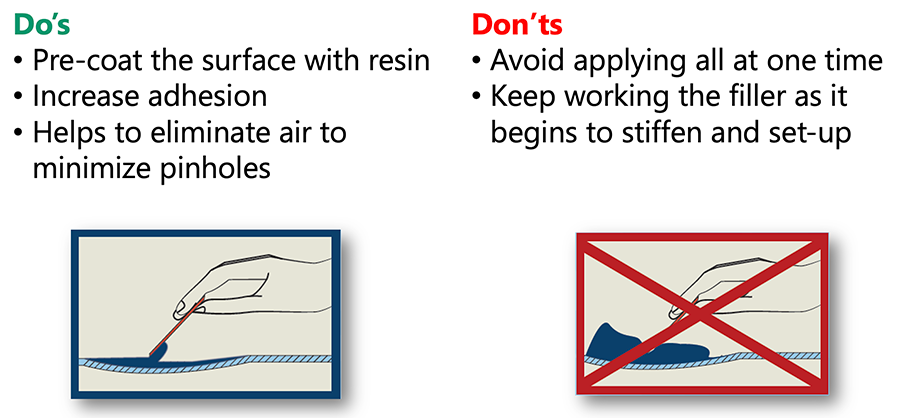

- Application techniques for improved performance

BEST PRACTICES FOR SAFETY

ALWAYS use the appropriate PPE

- Eye Protection for surface preparation (Flying debris and particulate-Grinding & Sanding)

- Hearing Protection

- Gloves for protection from solvents and materials

- Respirators for protection from

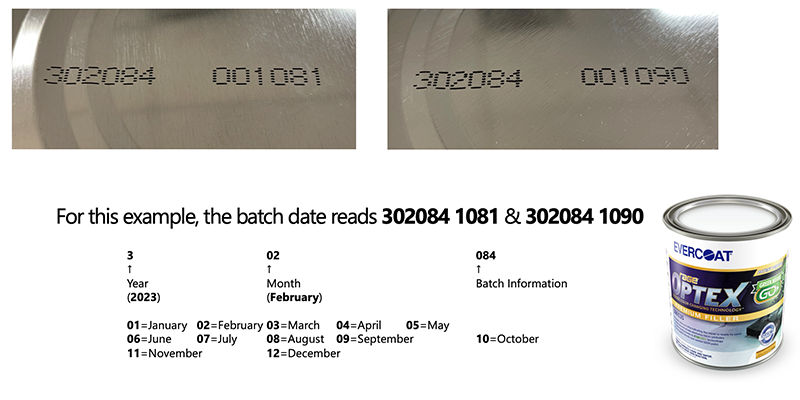

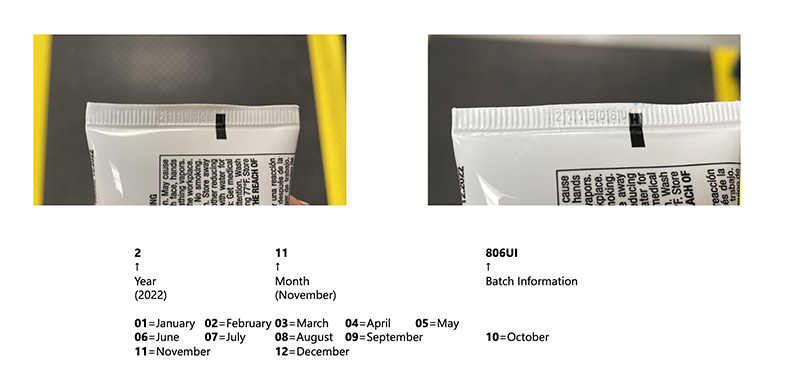

PRODUCT BATCH DATES

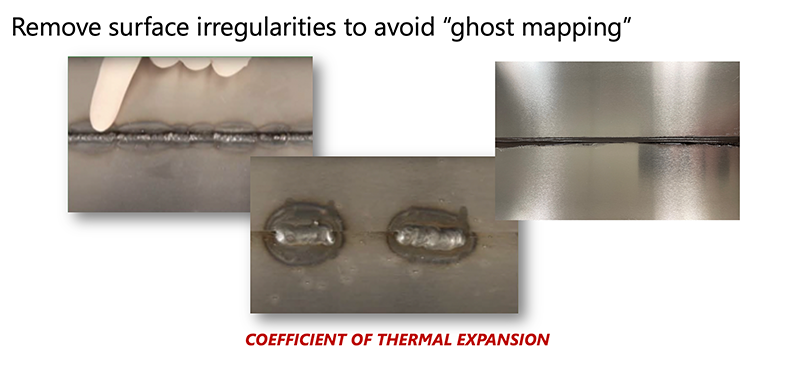

PROPER PREPARATION

Follow Vehicle manufacturer recommendations

Steel and Aluminum get treated differently

- Know the differences

- Should be repaired differently (Sanding vs. Grinding)

Grinding to aggressively remove the paint [because it’s faster] can damage the panel.

AVOID GRINDING!

- Use 80-120 grit for paint removal and general surface preparation

- Use 180-220 grit for featheredge areas

“Slow is smooth, Smooth is fast”

“Fastest isn’t always the best”

Things to avoid…

- Wiping the area with slow solvents

- Using prep wipes that etch the metal or leave a coating

- Applying an incompatible primer